Does Amazon Take Purchase Orders

Purchase Order & Transfer Orders Tips

One of the reasons many sellers don't make purchase orders is the amount of time it takes to create them, especially as the number of suppliers, orders and SKUs increase as you scale.

We've all been there.

Using many documents, spreadsheets, and files seems to just make everything more complicated and stressful. But it doesn't have to be!

When you have a system that streamlines your Amazon purchase ordering process, you'll be able to track any inventory that comes in and goes out of your warehouse or FBA with just a few clicks.

This way, you eliminate having to hunt through dozens of email threads to find your supplier orders. Having purchase orders well organized helps you to keep track of your orders to help you to follow up and ensure that you receive your goods on schedule. Using the data from your purchase orders (e.g., expenses, order volumes, and order/transfer frequencies) also informs your decisions and generates more accurate forecasts.

With that said, read on to learn how to simplify your Amazon purchase ordering process to improve overall business efficiency.

In this Amazon Purchase Ordering Process guide, we'll take a look at:

What is a Purchase Order?

PO for short, a Purchase Order is a document that lists the goods or services you want to buy from a supplier. It also acts as a binding contract between you and a supplier that agrees on the pricing and quantity of products you want to order.

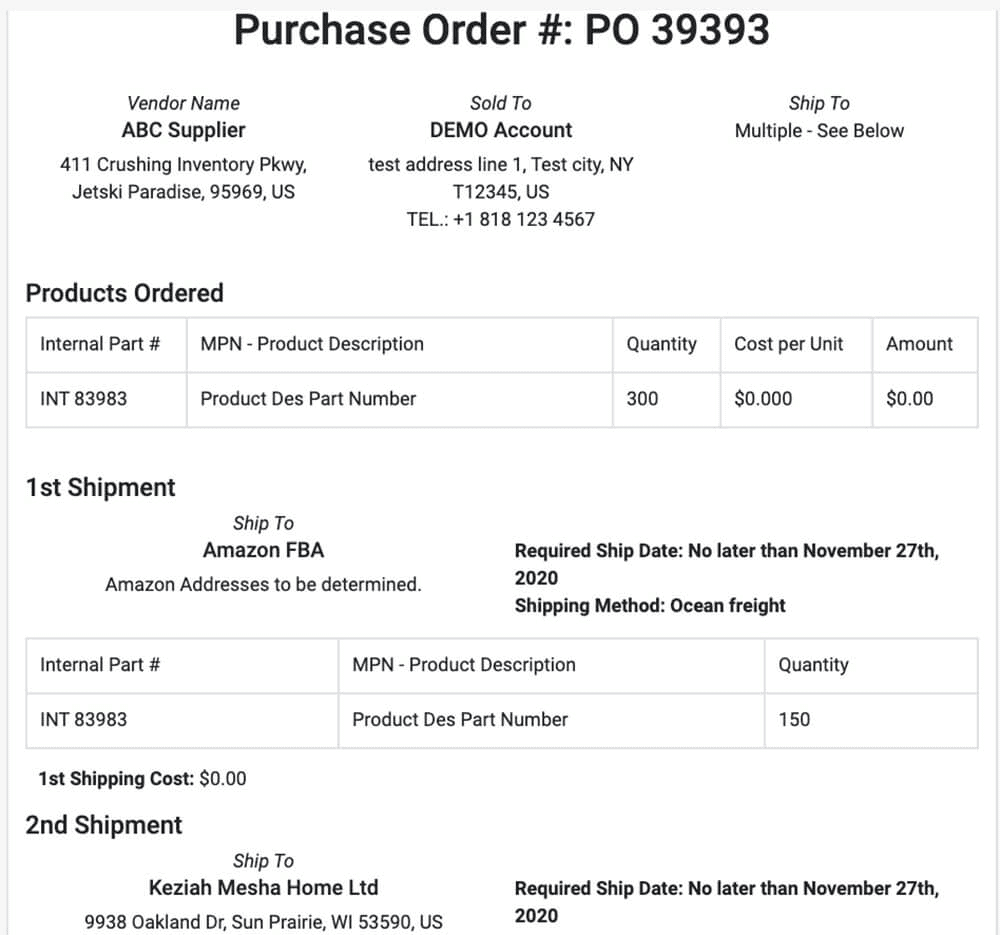

Aside from order quantity and pricing, purchase orders also contain a clear description of the product or service, payment terms, and delivery information. Depending on the template or PO system you use, you may also opt to split your shipment to different destination addresses within your PO.

Here's an example of a PO in SoStocked:

POs vs Invoices

You may think of a purchase order and an invoice as the same thing. They are similar. But a purchase order is essentially an invoice in reverse. Invoices are generally used to request payment from the buyer once the order/service is completed. In contrast, purchase orders are prepared and sent by the buyer to the supplier.

If you've been using invoices, you're probably wondering why you'd even want to start adding POs to your order placement process. It's just added paperwork, which is the last thing you need in your busy life. But actually there's a difference between invoices and POs, and that difference can go a long way toward increasing business efficiency and productivity.

POs and invoices usually work together in the order placement process. The purchase order number (PO number) should match the invoice number. That's why a purchase order is generated before the invoice in a typical ordering process. The invoice serves as a receipt proving that the supplier has fulfilled its responsibility throughout the PO process.

While there's nothing wrong with using invoices only, it doesn't give buyers much control over the order placement process. When it's time to restock your inventory, you want to ensure that your orders are received on time, and your requirements are communicated with your supplier properly. But doing all of that manually can be time-consuming, especially if you're managing multiple products.

With a purchase ordering system, you can automate repetitive tasks, including order tracking, so you won't have to waste time piecing together when your inventory is supposed to arrive based on back and forth emails with suppliers. POs and order tracking helps to ensure you don't miss your shipping deadlines and you know when to reorder inventory. And with a legal document like a PO, you can protect yourself from any dispute about the order and minimize communication issues that could cause production delays.

In sum, adding (and automating) a PO system to your procurement process can help you avoid common inventory pains that come from not tracking orders, such as under- and over-ordering, ordering/transferring too late, sifting through supplier emails, and juggling multiple spreadsheets.

4 Types of Purchase Orders

Standard Purchase Order (SPO)

This type of purchase order is used most often in single, one-time purchases. Buyers also make standard POs when there's a need for a sporadic order and an order where in-depth specifics are extremely important.

For instance, if you need to replace five office tables in your office, you may issue a standard PO to make a one-time purchase from a supplier. And depending on the size of your order, you may specify in your SPO whether you want to pick it up directly from the supplier or have it delivered to you to a specific location on a specific date. This one-off transaction will be completed once the tables are delivered in good condition.

So, in this example, your standard PO may include the following order details:

- List of items to be purchased

- Quantity of each item

- Price of each item

- Confirmed delivery date for each item or entire SPO

- Confirmed delivery location for each item or entire SPO

- General terms and conditions

You can get extremely specific with your standard PO, which you cannot do with other types of POs (more on this later). That's why SPOs are considered the most detailed PO type and are best used in instances where buyers are 100% sure about their order requirements.

Pro tip: Some sporadic orders may be too small (in quantity) to require a standard PO at all. Instead, you may just file them as basic expenses on your financial statement to cut down your processing time while keeping a clear documentation of your purchases. But as always, it's still best practice to check your company policy before deciding not to use standard POs for small sporadic orders.

Blanket Purchase Order (BPO)

Unlike standard POs, blanket POs are used when you need to order goods from a supplier on a recurring basis with a predetermined price over a long period of time. This is also why BPOs are also known as standing orders, open orders, and maintenance contracts.

A BPO typically includes:

- List of items/service to be purchased

- Terms and conditions (e.g., covered period of time)

It may also feature predetermined pricing and bulk discounts.

Let's say your office needs monthly tech maintenance and repair. In that case, you may use a blanket PO to specify the service you need, fixed cost for the service, and terms and conditions.

BPOs can also include multiple delivery schedules over a specific period of time when used to consolidate multiple standard POs into a single purchase.

As you can see, the ideal time to use a BPO is when you need to order repetitively from the same supplier, when there's a fixed price, quantity, and specific timeframe for reordering, and the orders require multiple deliveries.

In a way, blanket POs can help improve your overall procuring efficiency and reduce repetitive efforts, as well as the administrative costs associated with repetitive order processing.

However, as sales fluctuate over time, be quite careful with this one to ensure you do not contractually over or under commit yourself.

Planned Purchase Order (PPO)

PPOs are similar to SPOs, in that you can be specific about your order requirements. The difference, however, is that PPOs don't include confirmed delivery dates or locations. What you may indicate instead is unconfirmed, tentative delivery information for your item(s).

When these tentative delivery details are confirmed, a "release" against your PPO is issued to confirm your order's delivery date and location. In business, a release simply means your order is ready for processing, from production to shipping and delivering the units to you.

When to use PPOs?

A Planned Purchase Order is ideal for buyers who know their business will require a specific product or service in the not too distant future.

It is important to note that all types of POs become legally binding when a vendor or supplier accepts them. Therefore, you can use your PO against the other party in the event of a legal dispute. Meaning, if they failed to deliver on their promise. At the same time, they can use it against you too so be sure you are willing to commit to this agreement.

Alternately, a safer approach is to instead provide an estimated order schedule for 6 months to 1 year in advance. This schedule would not be legally binding but would be extremely helpful to you for your own inventory, sales and cash flow planning, as well as to your supplier because they'll be able to plan out their logistics, raw materials, and labor ahead of time. Such a schedule can be accessed through SoStocked on a rolling 12-month basis.

Contract Purchase Order (CPO)

CPO is basically a contract between two parties seeking to form a long-term commercial relationship. It is quite similar to SPO and PPO, except it doesn't include the list of items to be purchased. This also means it doesn't include the quantity, price, and delivery information for each item.

What's typically included in CPOs is a set of terms and conditions between the buyer and the vendor, from which subsequent POs may be created. For example, if your supplier agreed to offer you a 10% discount for bulk orders over a certain quantity, you can raise a standard PO against the established CPO to be able to include the discount in your purchase order.

What's The Difference Between Work Orders & Transfer Orders?

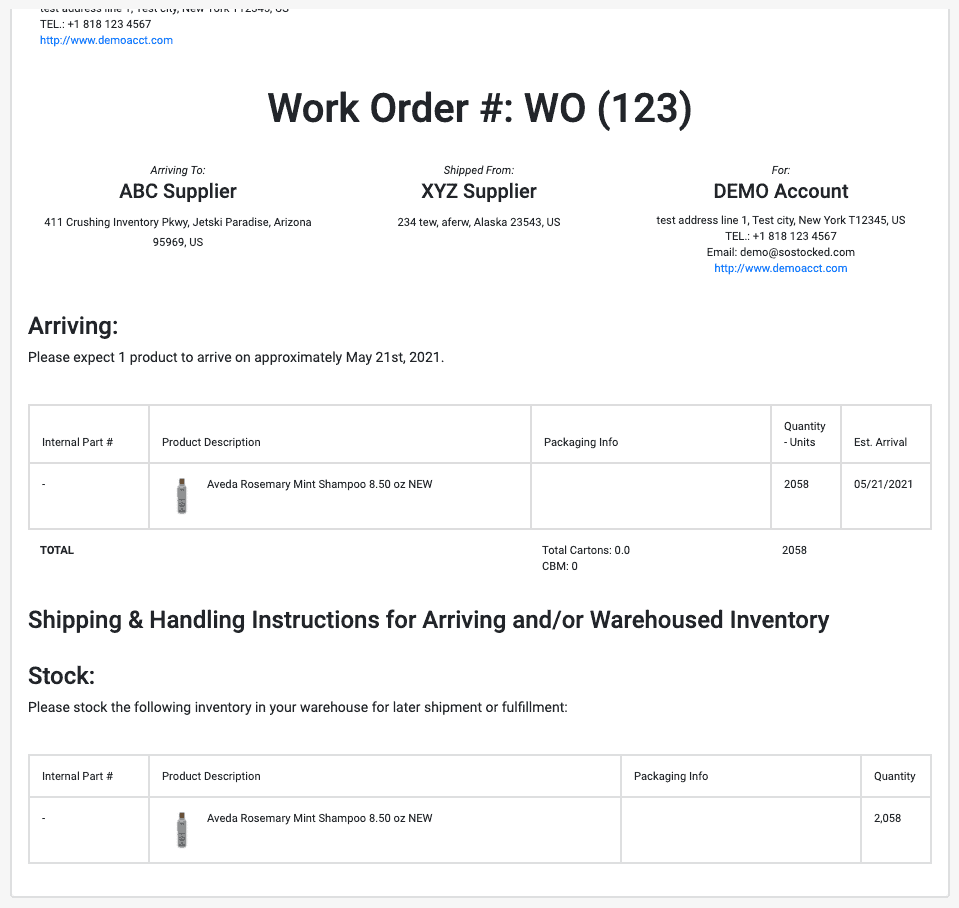

A Work Order (WO) is a document you send to your warehouse or prep center that gives them instructions on what to do with your existing (already purchased) and incoming inventory. Work orders typically provide details about what you want your warehouse to do with this inventory, including having them:

- Store your inventory

- Prep inventory

- Bundle multiple items into a single pack (also known as kitting)

- Ship your inventory

- A combination of any of the above requests

Let's say your shipment has just arrived at your 3PL warehouse, and you want to bundle four items into a single sellable pack. In that case, you need to send a work order to your warehouse to let them know about your product bundling requirements.

Thus, a transfer order (TO) is merely a type of work order that provides information about:

- The movement of your goods from 3PL or prep center to another location (e.g., Amazon FBA).

- The transfer of your items from one warehouse to another.

Basically, you use transfer orders once your goods are ready for shipping from your warehouse to another location.

Overall, Work Orders are beneficial for businesses that utilize third-party warehousing services. This document facilitates clear and seamless communication between you and your third-party warehouse or fulfillment center, improving your inventory management process.

Note: Work Orders or Transfer Orders are not to be confused with Purchase Orders. As mentioned earlier, a PO is an order request for the new inventory to be purchased and shipped from a supplier. A TO/WO is a document containing instructions on the work your warehouse needs to do on your incoming and existing inventory. These may include storing, repacking, bundling, or shipping it. Watch this video to learn more about work orders. I'm also going to discuss how WOs work inside of SoStocked later.

Why Use Purchase Orders?

Increase Purchase Ordering Efficiency

Stop digging through your email and trying to piece your order/transfer details. Instead, use a reliable Amazon purchase ordering system!

Once you've set up a system, it's easy to add SKUs, ASINs, or FNSKUs to your purchase orders and store all your purchasing records in a single location.

You'll also save a lot of time by using a PO system. It can help you to streamline PO creation and order placement for new orders and auto-generate POs for recurring purchases.

Then, when your shipments arrive, all you have to do is check the supplier's invoice against your POs to ensure your orders are correct, particularly quantity, price, status, and location. This will go a long way toward minimizing your risk for overstocking and stockouts.

Improve Inventory Management

Putting a PO order system in place makes inventory management less of a pain in the neck.

POs help you keep a close eye on what orders should be arriving at Amazon or 3PL warehouse. Once those orders arrive, you can then match the details in your PO against the supplier's invoices to spot inventory discrepancies early. If there's a mismatch, such as missing units, you can quickly launch an investigation to find out what happened (e.g., supplier shorted inventory, warehouse theft, etc.) and work to resolve the issue with whoever's at fault. So not only is PO an effective way to track your inventory order progress, but to also rectify discrepancies.

- What's in production?

- What shipments are arriving at your warehouse or Amazon?

- Who has your inventory? Supplier? Freight forwarder? 3PL?

- What's been ordered from your manufacturers that you're still waiting to receive?

If you have an excellent PO system, you can quickly find out where each PO or shipment is at a glance, including crucial details such as expected ship date, expected arrival date, inventory value, mode of transport (sea, air or ground) and other vital order data.

Help with Inventory Planning

Keeping your purchase order records helps you plan for the future. You can use the data from these records to gain insight into your business performance, specifically to examine company spending, purchase order cycles, and true supplier lead times.

If you need to reassess your lead times, you can look back at past PO dates and arrival times and reassess your current lead times based on what actually happened. Using this information can be vital in ensuring that future orders will be placed with enough time for them to arrive before stocking out.

Manage Company Spending Better

Comparing your old and new purchase records will also expose potential problems on the financial side of things, such as price increases that can impact your budget.

Are your prices increasing over the months or years? Identifying price increases over time will help you to decide whether to continue ordering a product or not. It will also help you to realize that you should be delving into how to lower costs in other points along your supply chain to maintain healthy profit margins.

With POs on hand, you can examine your supplier pricing history. As you observe prices increasing, you will know it's time to talk to your supplier, negotiate better rates, look for new suppliers or explore other options.

Overall, when you have a record of your transactions with suppliers, it makes tracking your PO-related expenses easier. It can also aid you in resolving disputes more quickly should they arise.

Minimize Communication Issues with Suppliers

POs become legally binding when a supplier approves them, protecting both parties from any mix-up when processing inventory orders. Mix-ups can happen when an employee misinterprets an order communicated through a phone call. Luckily, you can avoid this problem by providing your supplier with a written document of what you ordered and at what price.

And in the event of any dispute, you can reference POs for clarity. Providing documentation allows you to fix misunderstandings within your purchasing team and issues that may arise between you and your suppliers.

How to Simplify Your Amazon Purchase Ordering Process

Creating purchase orders doesn't have to be a complicated process. Follow these purchase order management best practices to simplify your FBA business operations.

Create a Workflow

A workflow enables you to outline the steps that your team needs to follow to get tasks done. Here's an example of a typical purchase order workflow for a new product:

- Run a forecast for the product(s) you are sourcing to determine your initial order

- Analyze and select a supplier

- Negotiate terms with the chosen supplier

- Create a purchase order

- Receive and check the invoice to see if it matches your PO

- Accept invoice and release initial payment to the supplier

- Track and receive orders, reconciling to ensure all inventory is received as expected

- Issue final payment to close out the order

- Keep a record of your purchase orders

Note that the exact PO process for your FBA business may look different depending on your needs. For example, you might require your purchase manager to get your approval for POs that exceed a certain budget limit.

Pro tip: If you're a SoStocked user, here's a detailed guide to creating POs or WOs within the software.

Automate Your PO Process

Automating repetitive tasks like purchase orders is the best way to increase productivity and avoid costly errors.

When your team spends more time than necessary on POs, it takes their focus away from revenue-generating tasks, such as sales and marketing. Plus, relying solely on Excel to manage POs is risky as up to 90% of all spreadsheets contain errors that affect the accuracy of their results. For instance, a cut-and-paste error in a spreadsheet cost TransAlta $24 million!

In addition, processing POs manually (e.g., emailing POs for approval from one employee to another) while ensuring they don't get lost during the process is exceedingly tedious, with serious consequences. An APQC study shows that manual purchase order processing can cost some companies more than $506.52 per PO.

Automating your purchase order process minimizes your risk for these errors and missteps. It also saves your team time that they can spend on other essential tasks, especially those that can't be automated.

In SoStocked, you can create POs and track them using the Order Tracker Dashboard. You can also assign a lead time to your supplier, adjust the ETA as needed, and add notes to your purchase orders. Click here to learn more.

Incorporate Lead Times into Your POs

Lead time in inventory management refers to how long it takes to receive your inventory once your purchase order has been placed.

In SoStocked, you can add lead times to your POs and build a "Lead Time Flow" so that the software can track your orders through their various phases (in production, ocean freight, ground shipping, and warehouse or FBA) and how long until it arrives at its final destination. This lead time flow is the standard for many private label sellers.

If your lead time doesn't include a 3PL or prep center, meaning your inventory goes straight into FBA, your lead time flow in SoStocked would look like this example below:

- In production: 30 days

- Ocean freight: 40 days

- Ground freight: 5 days

- FBA check-in: 10 days

Alternatively, you can also build a different lead time for shipments that include 3PL warehouses or prep centers. For example:

- In production: 30 days

- Ocean freight: 25 days

- Ground freight: 5 days

- 3PL warehouse: 5 days

And then, create a Transfer Order when it's time to ship out your goods from warehouse to FBA.

We've also seen many sellers use unique lead times due to lower Amazon restock limits and supply chain delays. For instance, some sellers hold back some units at their supplier's warehouse to airship to their destination country if their ocean freight gets held up at the port.

Your PO system should allow you to split your PO inventory into multiple shipments if needed, creating logistics flexibility to deal with changing conditions.

Given the chaotic times we're in, you should definitely ask your supplier if they're willing to hold a portion of your shipment at their warehouse as a contingency plan. Oftentimes, they are especially if this means you will be placing larger orders to account for this split.

Create Work Orders/Transfer Orders if using 3PL or Prep Center

If your lead time directs your shipments from a supplier to FBA, then you don't need a work order because no other party (third-party warehouse or prep center) is involved in handling the cargo aside from your supplier or freight forwarder.

But suppose your workflow requires that you send your inventory to a warehouse for repackaging and storage. In that case, you must create a work order. This document may contain a list of instructions on what your warehouse needs to do with your inventory, such as repackaging, bundling, or shipping it.

You might think of work orders as another tedious piece of paperwork. But in advanced programs like SoStocked, the software will automatically create a work order for lead time flows that include a warehouse or prep center that can then be emailed directly from the software. Not having to type up instructions to send to your warehouse actually saves time and reduces confusion.

Here's an example of a work order in SoStocked:

To create a WO in SoStocked, go to Orders, open the Order Tracker dashboard, click the "+" button located at the top left corner and select Work Order.

Set Your Min/Max Orders for Efficient Restocking

By setting your minimum and maximum order, you'll be able to predict how many units you want to keep at FBA, 3PL warehouse, or prep center, when to place a new purchase order and when to transfer inventory into FBA.

In SoStocked, your min/max can be based on the number of days of stock (calculated from your forecasted sales velocity) or a total number of units. Calculating min/max in days rather than in units is strongly recommended as your inventory levels will change based on your sales velocity.

Either way, SoStocked makes calculating your ideal order quantities and establishing optimal order/transfer frequencies much easier than using manual processes. The system also syncs data with Amazon through an API twice a day to provide you with the freshest information. Using your Amazon sales data and your own customizable settings, it will alert you when you need to place an order to ensure you don't stock out.

Manage POs Easily with SoStocked

Streamline your order and transfer processes with a system that allows you to create purchase and work orders!

SoStocked features a PO system with lead times for new inventory orders from your suppliers. Our secondary order management system that works in tandem with POs is our Work Order system, with transfer times for processing and shipping goods from a 3PL warehouse or prep center to FBA.

Without POs or WOs, it'll be challenging to track your inventory orders throughout the supply chain process. Other software tools and features that can be useful in monitoring your shipments include:

Order Tracker

Built into SoStocked to work with your PO and Work Order systems, the Order Tracker helps you track the progress of your inventory order from the moment the PO is placed through production and shipping to its final destination. This dashboard features a Kanban board that automatically moves orders and shipments from In Production to En Route to 3PL warehouse and FBA based on your custom set lead times.

Inventory Page

This page features Inbound Shipments and Inventory On-Hand Dashboards. Our Inbound Shipments dashboard shows you what POs/WOs are in production and where it is going: Amazon FBA or your warehouse.

The Inventory On-Hand Dashboard, on the other hand, lets you view all your on-order and shipped inventory and available stock at your third-party warehouses and FBA fulfillment centers, including items in reserved status.

Integrate Purchase Orders into Your Ordering Process

Purchase orders play a significant role in ensuring you receive the inventory you need to run your Amazon FBA business and receive them on time. They enable you to track shipments and quickly follow up on POs to keep them on schedule.

While creating POs may seem laborious, you can simplify your Amazon purchase ordering process with SoStocked. Not only will this improve productivity, but it will also help you to avoid costly spreadsheet errors.

1,000+ Customers. Free Data Migration. 1-on-1 Onboarding.

Need more information?

- Send Message: We typically reply within 2 hours during office hours.

- Schedule Demo: Dive deeper into the nuances of our software with Chelsea.

- Join Live Upcoming Webinar: New to Amazon inventory management? Learn three inventory techniques you can implement right away.

Does Amazon Take Purchase Orders

Source: https://www.sostocked.com/amazon-purchase-ordering-process/

Posted by: carsonarring1990.blogspot.com

0 Response to "Does Amazon Take Purchase Orders"

Post a Comment